EAM vs CMMS, is MCe an EAM, a CMMS or both?

Created: 2024.07.18

MCe is, and always has been both a EAM and a CMMS, it has features to allow the UX to be optimized for those that are more interested in the EAM aspects and those more interested in the CMMS aspects, as well as those managing the GIS.

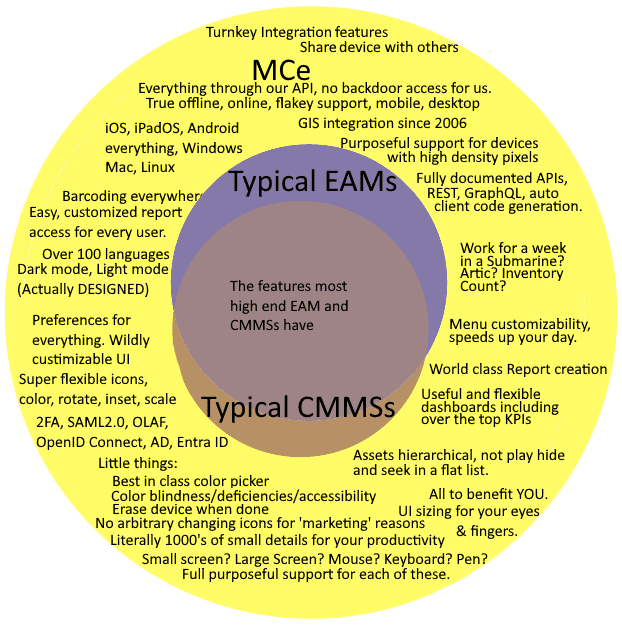

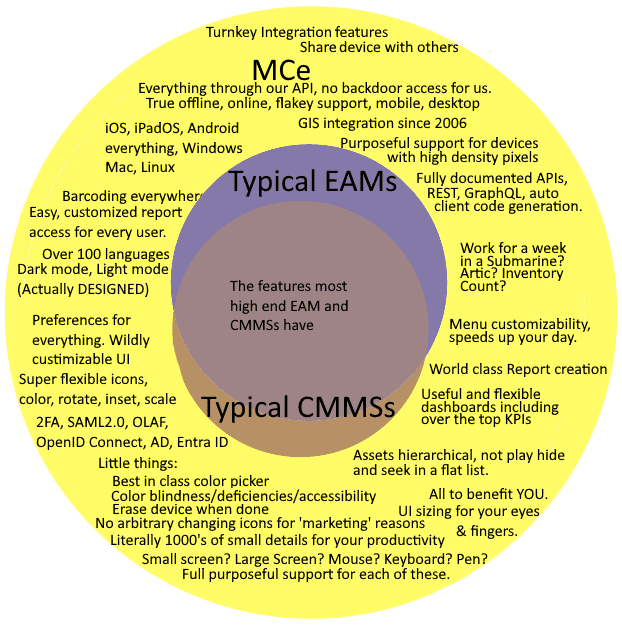

First as an overview

This diagram shows the overlap between EAM and CMMS. Depending on who draws it, they'll draw the 2 circles larger or smaller relative to each other (EAM only systems will typically draw the CMMS much smaller) and with more or less overlap (EAM only systems will show almost nothing for the 'CMMS only' part of the diagram.)

The point is not so much what impression you get from the sizes of the circles or the amount of overlap. The point really is, that if you get an EAM only system - you are losing out on proper management of your assets on a day to day basis, and if you are a CMMS only, you are losing out on the long term management tools.

While some companies it makes sense to have 'just a simple CMMS, not all that EAM stuff', it never makes sense to have 'just an EAM'.

If you are maintaining data and spending time and money with an EAM - it makes no sense to say "But I don't care about fully managing these assets I am spending so much time planning long term for." having an EAM only is like having the instruction manual for a fleet of cars, then not keeping track of when to get all the maintenance done. (Oh well, we have a plan to buy a new one if it fails due to bad maintenance.)

Now lets look at some details

So what IS the difference between an EAM and a CMMS, an Enterprise Asset Management system and a Computerized Maintenance Management System?

Up front, let's be clear, it is easier to define at a conceptual level than at a specific features level. Some CMMSs have EAM features that some 'just an EAM' products don't even have, and some EAMs have CMMS features that almost every CMMS is missing.

At its simplest: An EAM is concerned about the whole life cycle of assets, and not so concerned about the day to day management and maintenance. A CMMS is more worried about 'now' then the life cycle. A EAM/CMMS can either bring the best of both together or be a compromise, all depending on what the objectives are.

MCe choose for our clientele to go the 'best of both' route, giving tools and options for those that just care about EAM and those that 'just want to get and keep the equipment working" CMMS. It allows those in a company concerned about the lifecycle to work in tandem and use the data collect by those who just want to keep the equipment functioning efficiently and as much of the time as possible.

Features designed to help keep equipment running without interruption, fix it when it breaks, collect data about it, tools for managers to manage the ongoing maintenance are in the field of the CMMS. Features designed to determine when to replace the equipment, plan for changes in strategy, manage decisions across departments will look to the EAM features.

Neither CMMS nor EAM is 'better', in general, if you only need one - you need a CMMS, the larger your asset base is, the more likely you also need EAM features.

MCe can run without the EAM features being used, and to a lesser extent it can run without the CMMS features being used. But the best results are when you use the set, along with GIS or mapping depending on your needs, IoT and reporting sub systems.

So why would products be called 'CMMSs' when they really are both CMMS and EAM? Marketing. The term 'CMMS' historically is far better known, the term EAM is more likely to evoke the response "What is EAM?" so saying 'CMMS' even when you are an EAM or both an EAM and a CMMS like MCe just leads normally to less confusion. Similarly, most EAMs are really a combination of an EAM and a CMMS. You will be hard pressed to find a stand-a-lone EAM, though there are lots, especially in the low end pricing and functionality, that are CMMS only.

One quick filter to see if it is a high end EAM: Does it have an Asset tree? If the origination of your asset data is "just" geospatial, or 'just' a list with fancy filters, you are looking at a mid to low end EAM. Even good CMMSs have this.

One quick filter to see if it is a high end CMMS: Can you offline create a work order with procedure, execute the work order and complete it or do you have to be connected at steps along the way? Noting that most CMMS that say they have Mobile or OFFLINE really aren't talking about true offline capabilities, this can be seen by RFPs that ask if the mobile offering can lose data if added while offline and whether you can fully fill out a WO offline - not even asking the next step of whether you can create a procedure based WO and take it through to completion while offline.

MCe goes far beyond other EAMs in conveniently handling and reporting from an EAM perspective. MCe goes far beyond most CMMSs and is at worse par on some features with other high end CMMSs. (And of course way beyond the majority of just barely more than work order management tools that call themselves CMMSs)

Enterprise Asset Management (EAM) and Computerized Maintenance Management System (CMMS) are both crucial systems used in asset management and maintenance, but they differ in scope, functionality, and usage. Here's now a more detailed comparison:

Scope and Focus

EAM:

-

Comprehensive Asset Management: EAM systems manage the entire lifecycle of an organization's assets, from acquisition to disposal. This includes design, procurement, operations, maintenance, and decommissioning.

-

Enterprise-Wide: EAM systems are used across the entire organization and can handle multiple locations and asset types.

-

Strategic Focus: EAM emphasizes long-term asset planning and optimization, ensuring assets deliver maximum value over their lifecycle.

CMMS:

-

Maintenance Management: CMMS focuses primarily on the maintenance activities of assets. It is designed to streamline the scheduling, tracking, and documentation of maintenance tasks.

-

Departmental Focus: Typically used by maintenance departments and may not cover the entire organization.

-

Operational Focus: CMMS emphasizes day-to-day maintenance operations, ensuring assets are kept in optimal working condition.

Key Features

EAM:

-

Asset Lifecycle Management: Manages assets from procurement to disposal. Strategic Planning: Includes tools for long-term asset planning, budgeting, and forecasting.

-

Integration: Often integrates with other enterprise systems such as ERP (Enterprise Resource Planning), finance, and supply chain management.

-

Compliance and Risk Management: Helps ensure regulatory compliance and manage risks associated with assets.

-

Advanced Analytics: Provides in-depth analytics and reporting for asset performance, lifecycle costs, and more.

CMMS:

-

Work Order Management: Creation, assignment, tracking, and closing of work orders.

-

Preventive Maintenance: Scheduling and managing routine maintenance tasks to prevent asset failures.

-

Inventory Management: Tracking and managing spare parts and inventory needed for maintenance activities.

-

Maintenance History: Storing and managing the history of maintenance activities for each asset.

-

Mobile Access: Often includes mobile capabilities for maintenance technicians to access and update work orders in the field. Use Cases

EAM:

-

Large Enterprises: Suitable for large organizations with diverse and numerous assets spread across multiple locations.

-

Complex Asset Portfolios: Ideal for industries with complex and high-value asset portfolios, such as manufacturing, utilities, transportation, and healthcare.

-

Strategic Asset Management: Organizations that require a strategic approach to asset management, including capital planning and asset lifecycle optimization.

CMMS:

-

Maintenance Departments: Best suited for organizations where the primary need is to manage maintenance tasks and schedules.

-

Smaller Organizations: Suitable for smaller organizations or those with a more straightforward asset management requirement.

-

Operational Efficiency: Focused on improving operational efficiency and reducing downtime through effective maintenance management.

Integration and Customization

EAM:

-

Highly Integrative: EAM systems often integrate with other enterprise systems, providing a unified view of asset management across the organization.

-

Customizable: Offers extensive customization to meet the specific needs of different industries and organizations.

CMMS:

-

Stand-alone or Integrated: Can be used as a stand-alone system or integrated with other maintenance and ERP systems.

-

Less Customizable: Generally less customizable than EAM systems but easier to implement and use.

Summary

-

EAM is a comprehensive solution for managing the entire lifecycle of assets across an organization, focusing on long-term asset planning, strategic management, and integration with other enterprise systems.

-

CMMS is a more focused solution for managing maintenance tasks and schedules, primarily used by maintenance departments to ensure operational efficiency and reduce downtime.

Both EAM and CMMS have their unique strengths and are chosen based on the specific needs and scale of the organization. EAM with CMMS systems are more suitable for large enterprises with complex asset management requirements perhaps even needing GIS, Mapping, Reporting and IoT reading tooling added on, while CMMS is ideal for organizations primarily focused on maintenance operations.